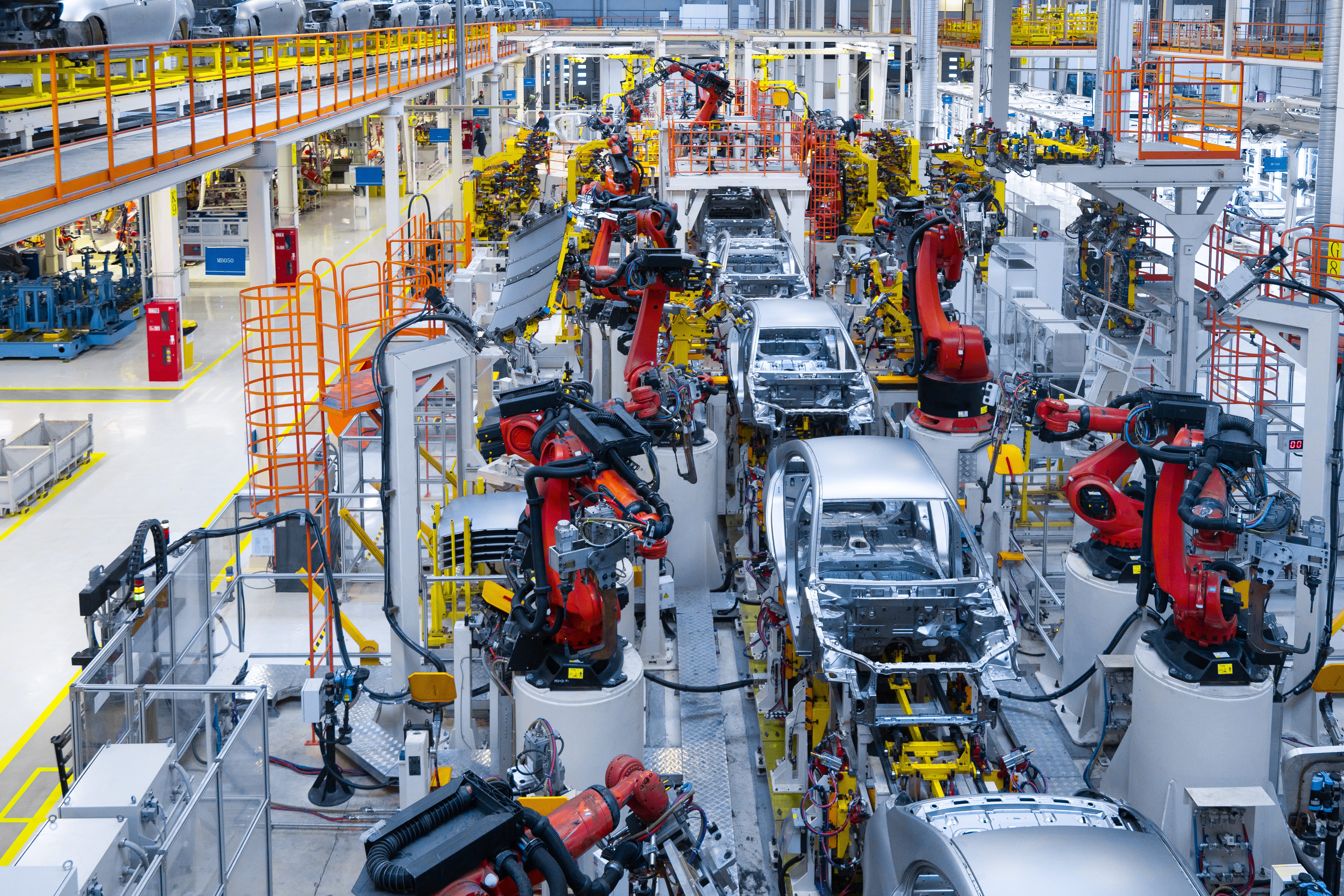

Production lines present unique challenges for automation, with objects moving continuously past the robot at variable speeds. This ingenious project from Inbolt incorporated RoboDK simulations for real-time industrial validation.

Time constraints are a constant juggling act for industrial applications. Adding a robot can improve the throughput of an entire production line, but the dynamic nature of factory lines can also present challenges for robotic automation.

Robots need to adapt to different line speeds, strict cycle time requirements, and variable object positions.

Inspired by challenges expressed by their clients, experts in vision-guided robotics, Inbolt has created a robust application for real-time vision using RoboDK.

Solving Real-Time Robotics Challenges on Moving Production Lines

Inbolt is a company specializing in real-time robotic vision and AI. Headquartered in France and the USA, the company was founded in 2019 after graduating from a pre-accelerator program in University of California, Berkeley.

The Inbolt team built this recent application around constraints and challenges regularly voiced by their clients.

Such constraints included needs to…

- Achieve specific cycle times.

- Adapt to varying line speeds.

- Accurately estimate cycle time.

- Ensure robot reachability of all target positions.

The team found these constraints were challenging to meet without performing physical tests, which would be time consuming and inflexible.

The Solution: Use Accurate Simulation to Streamline Cell Design

The complexities of moving production lines presented a unique opportunity for the team at Inbolt.

Several of the company’s clients were already using RoboDK to simulate their robotic stations. This presented an opportunity to simplify and improve Inbolt’s validation process.

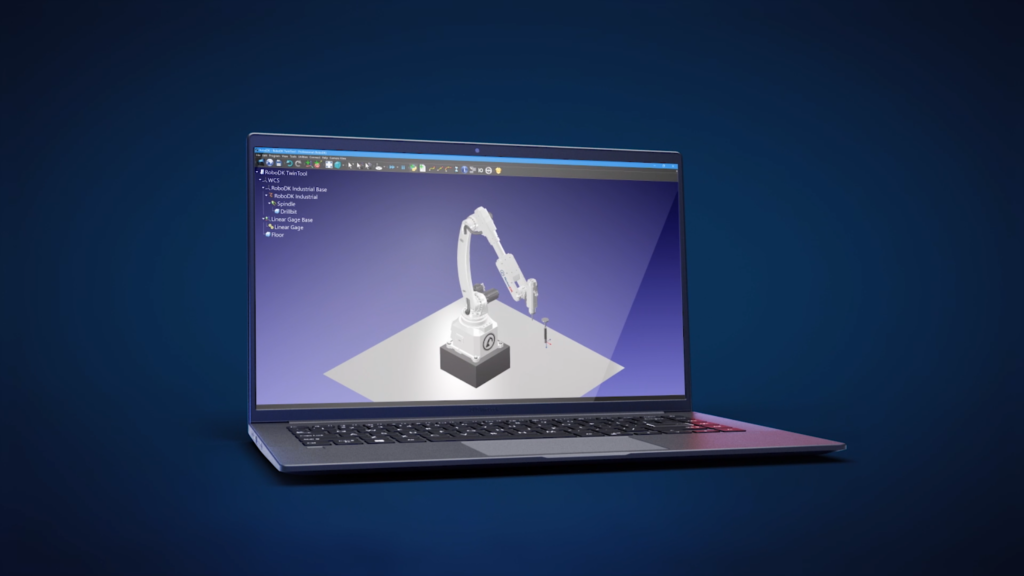

With RoboDK’s powerful simulator, they created a system for evaluating station configurations, ensuring a robot could consistently reach the required positions throughout its motion.

How the RoboDK Application Came Together

To build their application, the team at Inbolt followed a structured approach centered on creating an efficient, real-world-inspired process.

Features of the application included:

- Production line simulation with a moving conveyor to replicate factory conditions.

- Incorporation of a simulated camera to track parts as they move on the conveyor, providing real-time position data to the robot.

- Analysis of simulation results, such as cycle times, to refine the created robot program to align with client requirements.

In their test setup, the team programmed the robot to start working on parts as soon as they entered the camera’s field of view.

Following the data analysis, the team can quickly make adjustments to the application until they find the optimal setup.

As the system was centered on validating the feasibility of the system, RoboDK was the only software used, with no need for hardware integration at this stage.

5 Core Challenges of Dynamic Production that Inbolt Addresses

The solution that Inbolt built addressed some core challenges that are common when working with moving production lines.

Here are challenges they addressed:

1. Achieving Real-Time Tracking Accuracy

Synchronizing robotic movements with fast-moving objects on a conveyor can often lead to delays or tracking errors.

By integrating Inbolt’s 3D camera technology into the process, Inbolt could capture live positional data for accurate real-time tracking.

2. Handling Variable Line Speeds

The dynamic nature of modern factory environments means robots need to adapt to variable line speeds depending on the particular production line.

The solution allows the team to test and adapt to different line speeds in a simulated environment.

3. Removing Hardware Limitations

The traditional approach to creating such advanced robotic applications would require significant testing with physical hardware.

By using robot simulation, Inbolt created a feature that allows their Field Application Engineers to quickly test changes to their programs without costly physical testing.

4. Balancing Cost and Time Efficiency

Cost and time are always important factors when creating and testing robotic applications.

Using RoboDK allowed the team to both speed up their design process for clients and give them extra confidence before moving on to physical testing.

5. Validating and Optimizing Station Configurations

A significant benefit of the solution is how easy it makes validating and testing different station configurations.

The company’s Field Engineers can use a single software to test station configurations, validate them, and share the simulations with clients for better communication.

Why RoboDK Was the Right Choice

The team at Inbolt looked at various robot simulators before choosing RoboDK for the project.

They looked at both industrial and academic simulators and concluded that:

- Conventional industrial tools were too expensive, vendor-restricted, and required specialized training.

- Academic tools, although often open source, demanded advanced programming skills and a lot of customization.

Albane Dersy, Co-founder and COO, Inbolt, explains:

RoboDK was a great fit for this project because it made the simulation process straightforward and flexible. It let us test different station configurations efficiently, without requiring a physical robot or other hardware.

The ability to simulate the moving production lines and verify robot performance in real-time significantly simplified the company’s validation confidence. This both saved them valuable time and gave them extra confidence in their designs before physical testing.

What’s Next for Inbolt and RoboDK

This development is just the latest in Inbolt’s innovative solutions for industrial robotics.

The team plans to expand on this solution by applying a similar process to other dynamic industrial processes. They are also considering upgrading this solution by adding real-time depth camera to the data, allowing more detailed tracking capabilities.

This project represents a valuable approach to test and validate industrial robotics processes.

By using the power of RoboDK and combining it with their own expertise, the team at Inbolt transformed what could have been a lengthy and expensive challenge into a streamlined, future-ready solution.

Which of the challenges mentioned most aligns with your situation? Join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel