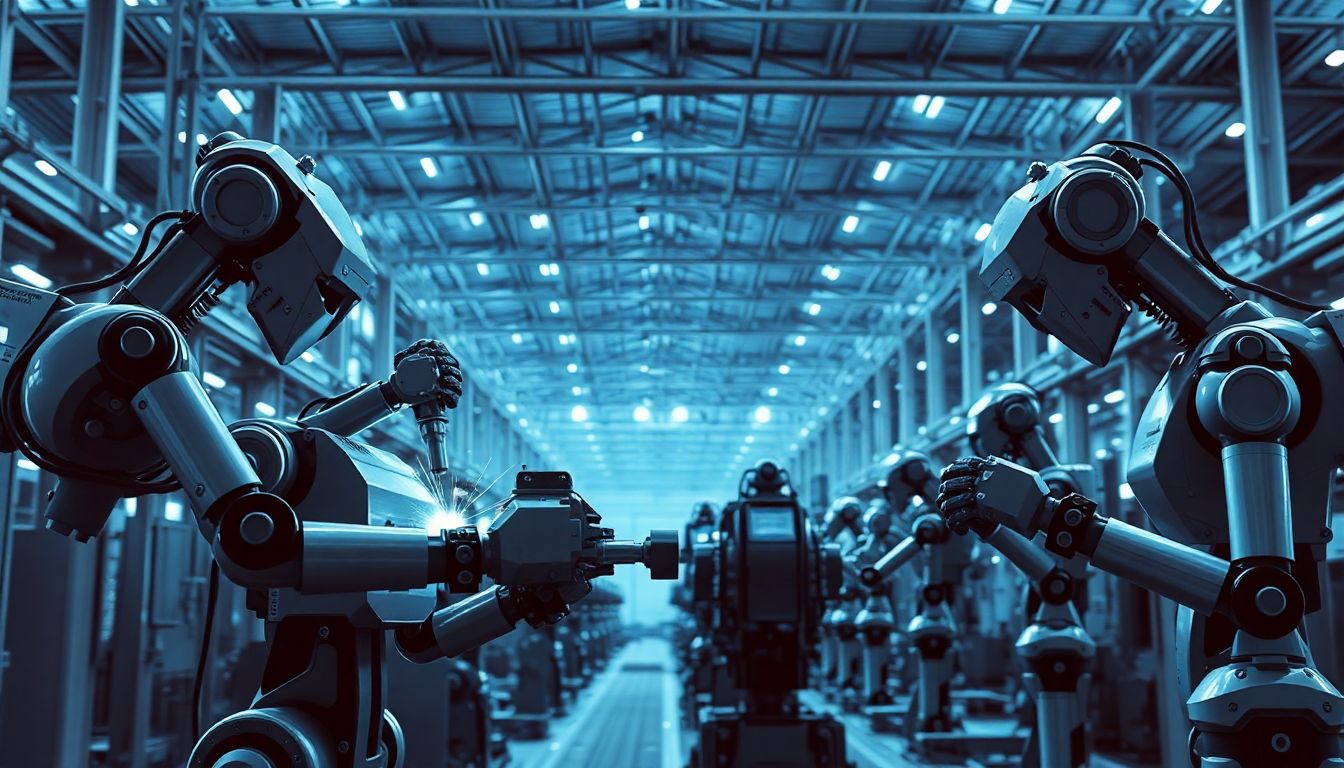

Imagine factories operating with unprecedented precision – fewer accidents, higher quality products, and optimized processes. This is the reality AI industrial robots are creating. These advanced machines boost efficiency, reduce costs, and enhance safety in ways that are transforming industries worldwide.

Today’s industrial robots are smarter, more adaptive, and capable of learning. Let’s explore how AI is revolutionizing industrial robotics and what the future holds for this transformative technology.

From Basic Automation to Intelligent Autonomy

Traditional industrial robots performed simple, repetitive tasks with no ability to adapt. Modern AI-powered robots learn from experience, make autonomous decisions, and operate with minimal human intervention – representing a monumental leap from basic automation to true autonomy.

Key AI Technologies Driving the Revolution

- Machine Learning: Enables robots to improve through data analysis

- Computer Vision: Gives robots the ability to “see” their environment

- Natural Language Processing: Allows understanding of verbal commands

- Deep Learning: Handles complex problem-solving tasks

Market Growth and Industry Adoption

AI robotics adoption is accelerating across sectors:

- Manufacturing assembly lines

- Warehouse sorting and logistics

- Healthcare facilities

- And many other industries

The global market for AI industrial robots is expanding rapidly with continued growth projected.

Transformative Applications Across Industries

Manufacturing Excellence

- Precision assembly with microscopic accuracy

- Automated quality control and defect detection

- Consistent high-quality output (e.g., BMW’s paint inspection robots)

- Faster production cycles

Logistics and Warehousing

- Automated Guided Vehicles (AGVs) for material transport

- High-speed sorting systems

- Automated packaging solutions

- Amazon’s fulfillment center robots processing millions daily

Healthcare Advancements

- Surgical robots enabling minimally invasive procedures

- Precision medication dispensing

- Automated laboratory testing

- Da Vinci surgical system assisting complex operations

Key Benefits of AI Industrial Robots

Unmatched Efficiency

- 24/7 operation without fatigue

- Error-free performance

- 50%+ productivity increases reported

Cost Reduction

- Minimized production errors

- Optimized resource utilization

- Predictive maintenance avoiding downtime

- Reduced material waste

Enhanced Workplace Safety

- Handling hazardous materials

- Operating in extreme environments

- Reducing worker exposure to dangerous conditions

Implementation Challenges

Financial Considerations

- Significant upfront investment

- Careful ROI planning required

- Strategic task allocation essential

Data Security

- Robust cybersecurity measures needed

- Secure data collection and storage

- Prevention of misuse

Workforce Adaptation

- Comprehensive training programs

- Developing human-robot collaboration skills

- Upskilling for new roles

The Future of AI Industrial Robotics

Emerging Technologies

- Collaborative robots (cobots) working alongside humans

- Advanced AI algorithms for better decision-making

- Next-generation sensors for richer data collection

Workforce Evolution

- Job market transformation

- New roles emerging

- Continuous learning becoming essential

Ethical Considerations

- Responsible AI development

- Transparent decision-making

- Fair implementation practices

Conclusion

AI-powered industrial robots represent a transformative force across industries, delivering unprecedented efficiency, cost savings, and safety improvements. While implementation challenges exist, the potential benefits make adoption increasingly essential for competitive businesses. As technology continues advancing, organizations that successfully integrate AI robotics while addressing workforce and ethical considerations will lead their industries into the future.