Automated paint systems are changing the way many industries apply coatings. These systems use robots and special spray equipment to paint products quickly, with consistent results, and less waste. Automated paint systems help save time, improve quality, and make the painting process safer for workers.

Businesses can pick from different automated solutions, with some designed to handle a wide range of part shapes and sizes using robotic arms or mobile trolleys. Modern systems can also mix and meter paint efficiently, so each item gets the right amount every time. For example, companies like Graco and KUKA offer advanced options for automated paint lines and robotic paint application.

Key Takeaways

- Automated paint systems boost productivity and paint quality.

- Different components and smart technology make these systems flexible.

- New trends continue to improve efficiency and safety in painting.

Overview of Automated Paint Systems

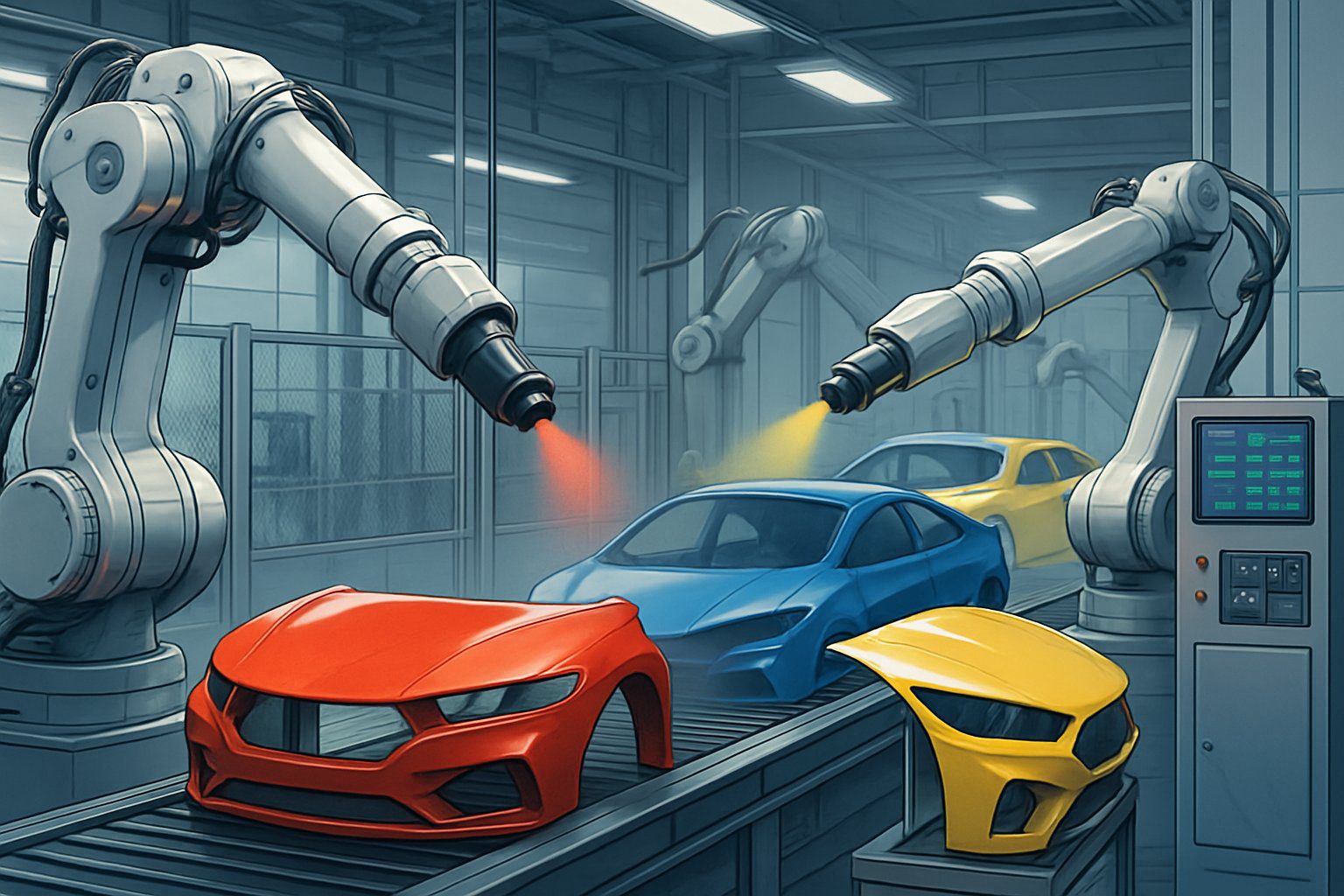

Automated paint systems use machines and robotics to apply paint without much human labor. These systems help companies save time, cut labor costs, and ensure products are painted evenly.

What Are Automated Paint Systems?

Automated paint systems are a mix of robots, sensors, and computer controls that handle the painting process. These systems include machines like robotic arms, spray guns, and conveyor belts. The entire setup is programmed so that each item is coated to the same standard every time.

Many systems let users set the exact area to be painted, such as by using four corner points or scanning the product. This setup can quickly switch between different jobs, which makes it flexible for use on several product types. These systems are often used in industries with high demands for speed and consistency, such as cars and consumer goods.

For more information on how these systems work, visit this page about automated paint systems.

Key Advantages of Automation

Automating the paint line improves efficiency and increases productivity. These systems paint items faster than manual methods, which means more products can be finished in less time. Automation also leads to lower operating costs because fewer people are needed to run the equipment.

Automated paint systems reduce mistakes and make sure each product looks the same. Sensors and controls let the machines adjust spray patterns or paint amounts as needed. Safety improves too, since workers spend less time around fumes and moving equipment.

Companies also save money on materials, as precise machines use just the right amount of paint. Less paint is wasted, which also helps protect the environment. Find more details about the benefits on this automated paint system overview.

Major Applications Across Industries

Automated paint systems are common in several industries:

- Automotive: Used for car bodies and parts, giving every piece an even coat and speeding up production.

- Furniture: Used to finish wood, metal, and plastic items, leading to high-quality results.

- Electronics: Coats products like phones and computers with protective or decorative paints.

- Appliances: Washers, refrigerators, and other home devices are painted quickly and efficiently.

- Aerospace: Aircraft parts need a smooth, even finish to meet safety and appearance standards.

These systems also appear in factories making doors, cabinets, or industrial machines. They handle both large batches and smaller custom runs, showing how flexible automated painting can be.

For more examples of where these systems are used, check out this look at industrial paint automation.

Core Components and Technologies

Automated paint systems use a blend of hardware, software, and special equipment to achieve fast, repeatable, and high-quality finishing. The core parts work together to increase output, improve coverage, and lower labor costs in industries like automotive and manufacturing.

Painting Robots and Robotic Arms

Painting robots and robotic arms are key for precise paint application. These machines can be programmed to move with accuracy, making them ideal for complex shapes and consistent finishes. Modern robotic arms allow for quick changes in position, speed, and spray pattern.

Robotic systems such as the Pro XP Auto Electrostatic Spray Guns and the ProBell rotary bell applicators attach to these arms for even, smooth coverage. They can also reduce paint waste and boost efficiency by spraying only where needed.

Many robots work in sync with automated conveyors. This ensures every product or part is painted the same way each time.

Key Benefits:

- Consistent and repeatable painting

- Reduces manual labor

- Handles hard-to-reach or complex parts

Paint Booths and Controlled Environments

A controlled paint booth is essential in automated systems. It helps manage air quality, temperature, and humidity. This keeps the paint application smooth and reduces dust or particle contamination.

Paint booths use advanced ventilation to keep fumes low and ensure a safe area for both equipment and any nearby workers. They also help recycle and filter air, which supports environmental goals.

With robotics, these booths include programmable features that coordinate with painting robots and spray guns. This setup is common in automated paint lines for cars and electronics, where quality standards are strict.

Common Features:

- High-efficiency filters

- Programmable climate controls

- Special zones for drying and curing

Spray Guns and Applicators

Spray guns and applicators deliver paint from the system to the product surface. Automated options include models like the AirPro Auto Air Spray Guns, AL Auto Airless Spray Guns, and Pro XP Auto Electrostatic Spray Guns.

Some systems use the AL Series Automatic Spray Guns for high-volume tasks. Others, like the Stellair Auto or AirPro EFX Air Spray Guns, focus on precise, small-area painting.

These tools can be:

- Electrostatic (which uses charges to attract paint to surfaces)

- Airless (uses high pressure for thicker coatings)

- Rotary bell (spins paint for a fine, even coat)

Each type offers unique benefits for speed, control, and coverage. Automated systems may switch between spray gun types depending on the task.

Advanced Mixing and Metering Systems

Accurate mixing and metering are central to automated paint processes. These systems use built-in controls, real-time sensors, and advanced technologies to deliver the exact amount of paint and hardener needed for high-quality finishes and efficient production.

Positive Displacement and Meter-Based Systems

Positive displacement and meter-based systems deliver precise control over paint ratios and volumes. The ProMix PD is a popular positive displacement system that can handle a wide range of viscosities. It maintains accurate ratios by measuring liquid movement with pistons or diaphragms, rather than relying on airflow or guesswork.

Meter-based systems, like the ProControl 1KE, use electronic sensors and digital controls. These systems can quickly adapt to changes in flow rates, making them valuable for projects with complex requirements or frequent color changes.

Both methods are valued for repeatability and low material waste. Proper calibration is essential, ensuring each batch meets the desired mix and minimizes errors. Positive displacement systems are often chosen for their reliability in industrial settings where consistency is crucial.

Integrated Mixing Technologies

Advanced mixing systems, like ProMix 2KS and ProMix 3KS, automate the blending of two or three mixed components before spraying. These systems help maintain consistency and reduce human error, providing accurate color matching and reducing off-ratio material.

Modern mixing technologies often use automated paint mixing machines that create a controlled environment. Technologies like the Intelligent Paint Kitchen coordinate pumping, agitation, and delivery, all managed by programmable controls. This setup delivers benefits such as exact color reproduction, reduced operator intervention, and improved material tracking.

Some systems feature multistage settings for high-viscosity materials, ensuring proper blending without settling or separation. These technologies play a vital role in industries where finish quality and uniformity matter most.

Flushing Waste and Cleaning Processes

Automated paint systems integrate flushing and cleaning procedures to reduce downtime and control waste. ProMix units are built with automated sequences that flush fluid lines between color and material changes. This process minimizes leftover paint in lines and helps save material costs.

Flushing waste is collected and separated for safe disposal or recycling. Automation controls the exact amount of solvent and flushing medium used, which reduces chemical use and helps maintain environmental standards.

Key features often include customizable flush cycles and rapid changeovers. Shorter cleaning times also lead to fewer errors and faster production rates. Regular, automated cleaning and waste handling are necessary for maintaining consistent output and reducing maintenance needs.

Automation in Material Delivery

Material delivery automation involves transporting paint from bulk containers or drums directly to the mixing system or spray equipment. Technologies such as Iniflex automate this process, maintaining pressure and flow without manual handling.

Automated delivery systems use sensors and pumps to transfer paints and solvents precisely where needed. This ensures the spray line always has a steady supply. Large operations often have central paint distribution panels or stations to manage several production lines at once.

Benefits include reduced labor, fewer spills, and less exposure to hazardous materials. Automated material delivery supports seamless integration with modern automated paint systems, increasing plant safety and improving productivity.

Performance, Efficiency, and Safety

Automated paint systems can deliver consistent, high-quality finishes while reducing waste and improving workplace safety. They also help factories get more done in less time with fewer errors.

High Precision and Consistent Results

Modern automated paint systems use sensors and programmed controls to spray paint evenly on every surface. Robots can follow the same path thousands of times, which keeps colors uniform from part to part. This high precision creates fewer defects and less need for touch-ups.

When equipment is set up correctly, these systems keep overspray and missed areas to a minimum. This reduces wasted paint and makes quality control easy. As a result, industries that need strict color matching—like automotive and electronics—can trust that every item meets their standards.

Advanced settings let operators adjust spray patterns, speeds, and paint mixtures. This adaptability supports different shapes and sizes, keeping results consistent even as products change.

Increasing Productivity and Speed

Automated paint lines work quickly and steadily. They can paint large batches of parts much faster than workers can by hand. Machines do not need breaks or shift changes, so they can run for long hours and finish more items in less time.

Speed and efficiency rise because automated systems deliver the right amount of paint at the right time. Operators can program the equipment to handle multiple colors or coatings without stopping production. Reciprocators and robots often work together so the paint is applied smoothly and repeatably.

By minimizing mistakes and rework, plants see higher output and less downtime. Data from automated spray systems shows that automation leads to faster cycle times and lower operating costs.

Protecting Employees and Work Environment

Automated systems reduce the need for workers to be near harmful chemicals and paint fumes. This improves safety because employees have less contact with dangerous substances, which lowers the risk of breathing problems and skin irritation.

Spray booths and paint robots are built with safety controls, like explosion-proof enclosures and ventilation. These features keep the worksite safer for everyone. Automation helps companies follow safety rules and protect staff health.

By enhancing worker safety and reducing chemical use, these systems also support cleaner air and healthier workplaces. Some facilities even see drops in workplace accidents after switching to automated paint lines.

Industry Applications and Material Considerations

Automated paint systems are used across many industries to deliver consistent finishes, control environmental impact, and increase production speed. The choice of equipment, paint application methods, and material handling affect coating quality and cost.

Automotive and Industrial Manufacturing

Automated paint systems play a big role in car factories and large industrial plants. These systems help meet strict quality standards by delivering even coatings and smooth surfaces.

In the automotive field, robots accurately paint car bodies, frames, and removable panels. Sensors and controls adjust the amount and thickness of paint to reduce waste and keep paint use consistent. This improves finish quality and helps manufacturers save money.

Factories that produce trucks, tools, and machinery use automated spray booths to keep up with fast production lines. The paint application can be tailored for different metals, alloys, or heavy equipment. Paint robots can also lower paint waste by up to 30%, which supports goals for less pollution and sustainability.

Special Substrates: Plastics, Glass, and Ceramics

Some materials need special attention during paint application. Plastics, glass, and ceramics require different spray techniques and surface treatments than metal.

For plastics, surface preparation is key to help paint stick and avoid peeling. Glass has a smooth, nonporous surface, so special primers or etching may be needed. Ceramics often require coating at high temperatures or using specific binders.

Automated systems have settings to handle these materials, changing flow rate, spray pattern, and temperature. This protects fragile items from damage. Different materials need unique paint types and application methods, making material knowledge critical.

Powder Coating and Advanced Applications

Powder coating is a type of automated paint application used for metal and some plastics. Dry powder paint is sprayed on a surface and then baked to form a hard layer.

This method reduces solvent use, so it creates less air pollution and waste. Powder coating works well for items like bike frames, metal furniture, and car parts. It can create thicker, more durable coatings than normal paint.

Modern systems use conveyors, enclosed booths, and recovery units to improve efficiency. Advanced set-ups support multiple colors, detailed masking, or quick color changes. Automated paint systems continue to develop better features for high-volume work and complex jobs.

Corrosion Resistance and Coating Thickness

Coating thickness is one of the most important measurements for automated paint systems. Too little paint can leave surfaces open to rust, while too much can chip or lose adhesion.

For corrosion resistance, automated systems carefully measure and control the amount of paint applied. Consistent thickness ensures steel beams, pipes, and car bodies stand up to weather, water, and chemicals.

Advanced systems can spray layers with different properties, such as primer for adhesion and topcoats for UV protection. They use feedback sensors to avoid weak spots. To meet strict industry requirements, careful control of coating thickness and quality is essential to long-lasting protection.

Future Trends in Automated Paint Systems

Automated paint systems are advancing through improvements in robotics, environmental technologies, and advanced customization. These changes make paint processes more efficient, eco-friendly, and adaptable to customer needs.

Next-Generation Robotics and AI Integration

Modern automated paint lines are using more advanced robots that can paint with greater precision and repeatability. AI-powered systems allow for faster changeovers, auto-adjustment to part variations, and smarter path planning. This technology can lead to more consistent coverage and less paint waste.

Compatible robots are now easier to integrate and work with a wide range of part shapes and sizes. Paint line automation helps reduce manual labor, lowers the risk of defects, and boosts overall productivity. Some manufacturers apply machine learning to predict maintenance needs, which decreases downtime and keeps systems running smoothly.

Key advancements include:

- Real-time monitoring for quality control

- Collaborative robots that work safely near humans

- Automated inspection tools for defect detection

For detail on these trends, see how the industry is shaped by advances in automation and AI.

Sustainability and Environmental Considerations

Eco-friendly practices are becoming standard in automated paint systems. Companies now favor water-based paints, high-efficiency filters, and closed-loop systems that cut down on solvent use and air pollution. These changes help meet strict environmental standards and reduce costs through recycling.

Sustainable systems offer:

- Lower VOC emissions

- Better paint utilization, using only what is needed

- Improved energy efficiency through smarter control systems

- Waste reduction using reclaim and filtering technologies

Switching to greener solutions also brings economic benefits by reducing waste and energy bills. Manufacturers are keeping pace with new rules by investing in eco-friendly finishing solutions.

Customization and Adaptability

Automated paint systems are more flexible than ever. They can rapidly switch between different colors or finishes and can adapt paint jobs based on order requirements. This is possible thanks to modular spray booths, programmable robots, and real-time data feedback.

Key features include:

- Quick-change nozzles for different paint types

- Custom programming for robotic arms

- Automated recipes for unique finishes

This adaptability supports smaller batch sizes and short turnaround times, which is important for both automotive and consumer products. Digital systems let operators monitor and adjust the line quickly, meeting diverse client needs as described in industry customization trends.

Frequently Asked Questions

Automated paint systems are changing how industries apply coatings and finishes to products, walls, and vehicles. Companies are considering cost, efficiency, and new technology when deciding whether to update or replace traditional painting methods.

What are the advantages of using a robotic spray painting system in industrial settings?

Robotic spray painting systems help lower labor costs and improve safety by reducing worker exposure to paints and fumes. These systems offer better control, leading to smoother and more even finishes on products.

They can also increase production speed. Automated robots are able to paint consistent, high-quality surfaces during long production cycles without fatigue.

How much does it typically cost to implement an automated paint system in a manufacturing line?

The cost can range from tens of thousands to several hundred thousand dollars. Pricing depends on the size of the system, type of robots, and the complexity of the project.

Additional costs may come from installation, programming, and ongoing maintenance. Companies need to plan for these expenses when considering automation.

What factors determine the best automated paint system to use for a specific application?

The type of product, desired paint finish, and required production speed are key factors. Facilities also need to look at available space, the kind of paint or coating used, and whether the system will need upgrades in the future.

Complex shapes or strict quality needs may require more advanced robots or special equipment. Companies often compare several systems before choosing the best fit for their needs, as described by experts at Robotic Paint Group Ltd.

How do automatic painting machines for walls differ from traditional painting methods?

Automatic painting machines use sensors, software, and hardware that reduce the need for manual skills. These machines can cover large wall surfaces quickly and with even layers of paint.

Traditional painters rely on brushes or rollers and require more time and physical effort. Machines often leave less mess and a more uniform finish compared to manual work.

In what ways can automated paint sprayers improve efficiency and consistency over manual painting?

Automated sprayers deliver steady paint flow and uniform coverage, cutting down on wasted materials. They can repeat painting cycles with the same quality on each product or surface.

By reducing human error, automated sprayers produce fewer flaws and save time on touch-ups and corrections. More details on common advantages can be found at Spray Direct.

What technological advancements are influencing the development of automated paint systems?

Modern systems use intelligent sensors, advanced control software, and improved robot arms for more precise applications. Better programming also allows the machines to adjust to new product shapes and different types of paints.

Newer models are easier to integrate into existing manufacturing lines. Technology improvements lower maintenance needs and boost system reliability, as described in articles about transitioning from manual to automated painting.